SIEKMANN elbows

special. elbow. production.

Pipe elbows according to EN 10253, DIN 2605 or ASME B16.9

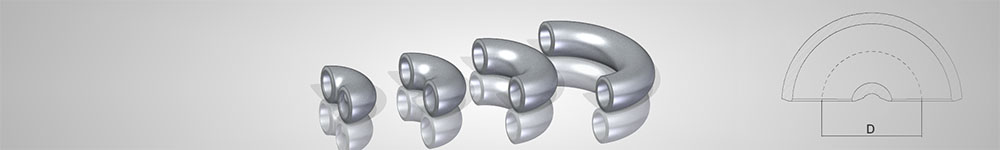

Siekmann has been offering pipe elbows made of seamless pipe, steel or stainless steel, in Germany for decades. Our strength lies in the forming of thick-walled pipe elbows as well as in the area of special pipe elbows. In addition, as a manufacturer, we keep a small stock of blanks. In addition, we can also offer you individual items at short notice. We also manufacture new products in small quantities and within very short production times.

Our delivery programme includes seamless pipe elbows with thick walls, special materials, special radii, bends with leg extensions. As well as pipe bends manufactured as 45, 90 or 180 degree bends (intermediate dimensions also possible). We are particularly specialised in the production of pipe elbows with full utilisation (type B) according to the standard EN 10253-2 or 10253-4 or part 2 according to DIN 2605. Our products are used in refineries, power stations, oil drilling platforms, heat exchangers, in mechanical engineering and in many other areas.

If you would like to buy pipe bends, please contact us. We will be happy to help you.

you will also find a form to request pipe bends directly from us.

Delivery programme pipe elbows:

| Outer diameter: | 14,0 mm – 219,1 mm |

| Wall thickness: | 1 mm to 50 mm, depending on outer diameter |

| Angles: | 15°, 30°, 45°, 90°, 180° and in between |

| Type: | Type 2D, 3D, 5D, long radius (LR), short radius (SR) – further bending diameters can be found under bending diameter |

| Standards: | EN10253 type A and B, DIN 2605 part 1 and 2, ASME B16.9, production according to customer specifications, |

| Tolerances: | In general, we manufacture according to the common tolerances of the pipe elbow standards. However, it is often the case that we also manufacture elbows with narrower tolerances. In this case we have the possibility, for example, to produce the pipe bend with a bending diameter of +/- 1mm. |

We supply seamless elbows made of carbon steel, high alloy steel or stainless steel. In addition, our extensive experience in heat treatment enables us to form a wide range of materials. By the way, you will find a list of materials in the materials section.

Our production is subject to strict quality controls. Dimensional checks are carried out during the manufacturing process. This enables us to detect faults all the earlier. Siekmann is monitored by TÜV Nord and is ISO9001:2015 certified. Because of this, we can guarantee continuous improvement.

Materials for elbows

Over the years, we have been able to gather a wide range of experience in the field of tube forming. Carbon steels, high-alloy steels and stainless steels are among our processing materials. Below you will find a list of the materials from which we can manufacture elbows:

EN / DIN()

- P235GHTC1/2 (St 35.8 I/ III), P265GH, S355J2H

- 16Mo3 (15Mo3), 10CrMo9-10 (10CrMo910), 13CrMo4-5 (13CrMo44)

- X11CrMo5, X11CrMo9-1, X20CrMOV11-1, X10CrMoVNb9-1, X10CrWMoVNb9-2, 7CrMoVTiB10-10

- P215NL (TTST35N/V), 12Ni14 (10Ni14)

- P355N (StE355), P355NH (WStE355), P355NL1 (TStE355), P355NL2

- L290NB (StE 290.7), L360NB (StE 360.7)

- 1.4301, 1.4306, 1.4361, 1.4362 (Lean Duplex), 1.4401, 1.4404, 1.4410, 1.4435, 1.4436, 1.4439, 1.4462 (Duplex), 1.4466 (Super Duplex), 1.4501, 1.4539, 1.4541, 1.4547, 1.4550, 1.4571 1.4841, 1.4749, 1.4828, 1.4878, , 1.4876, 1.4952, 1.4835, 1.4877, 1.4910

ASME

- WPA, WPB, WPC, WP1, WP5, WP9, WP11, WP12, WP22, WP32/27, WP91, WP92, WP304, WP304 H, WP304L, WP310, WP316, WP316L, WP316TI, WP321, WP347, WP347H

- WPL 3, WPL6, X42, X52, WPHY52, WPHY60

- S30815, S31000, S31050, S31500, S31726, S31803, S32760, N08904

- Alloy 800H, DMV310N

Standards for fittings and pipe bends

EN 10253-2

This is the current standard for fittings for welding in unalloyed and alloyed ferritic steels with special test requirements. Several DIN standards for different fittings have been combined into one European standard. Furthermore, the pipe bend part is decisive for us here. We deliver according to the types 2D, 3D, 5D and also many special radii in between. Furthermore, EN 10253-2 also includes a part for elbows with full utilisation (type B). “Type B” elbows have a significantly increased wall thickness on the inside of the elbow compared to the wall thickness at the welding ends, as the inside of the elbow is the most heavily stressed area in an elbow. The standard also includes various options that can be specified.

For example: Option 15 – Each fitting shall be hardness tested.

EN 10253-4

This standard deals with fittings for welding made of austenitic and austenitic-ferritic (duplex) steels with special test requirements. For the most part, this standard corresponds to EN 10253-2. In addition, however, there are, for example, occasionally different bending radii compared to EN10253-2. Consequently, our team will be happy to inform you about the differences. The options explained in EN10253-2 are also included in -4. However, they differ fundamentally.

Option 15: An inspection certificate 3.2 according to EN 10204 shall be issued.

DIN 2605

DIN 2605 is the former pipe bend standard that has now been replaced by EN10253. Here, different wall thicknesses apply to the elbows with full utilisation compared to the new standards. This standard is also not as comprehensive as EN10253 and only includes a section on elbows and no other fittings.

ASME B16.9

This standard contains all technical delivery conditions for fittings manufactured according to ASME standard. Among other things, here is also a part for the elbows. The wall thicknesses are given in “schedule” series and the outside diameters in inch dimensions.

What is a pipe bend?

A pipe bend is a pipe fitting that is used to enable changes of direction in pipework systems. There are various types of pipe bends, which can differ in terms of outer diameter, wall thickness, bending radius, angle and material. They are typically made from either welded half-shells or seamless pipe. Pipe bends are used in various areas such as power plant construction, mechanical engineering, heat exchanger and plant construction, and more.

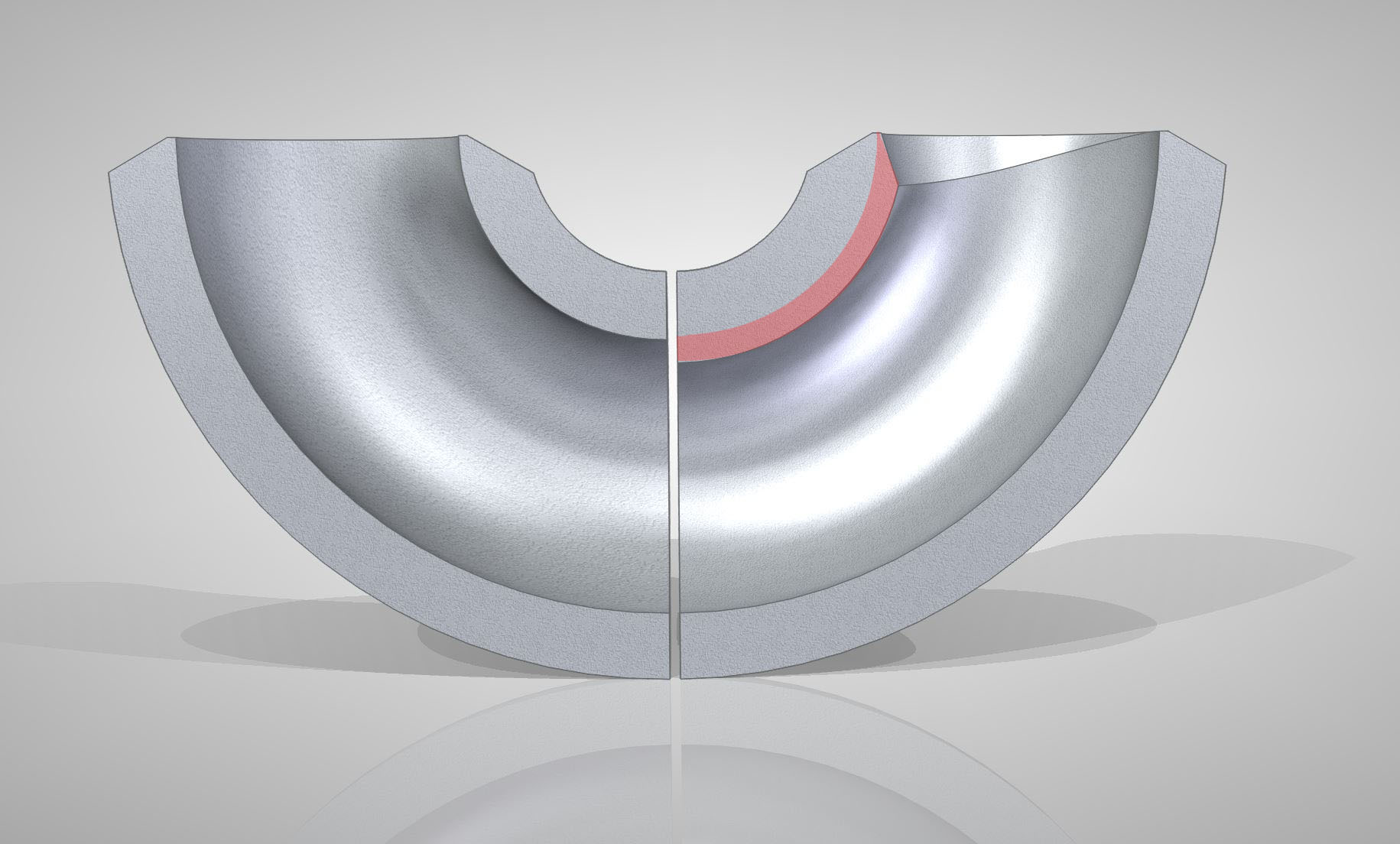

Pipe Elbow Type A – Type B Difference

Type A pipe bend:

The fittings have the same wall thickness at the weld ends as at the bend body. The resistance to internal pressure is less than that of a pipe of the same outside diameter, wall thickness and material. For this reason, they are also referred to as pipe bends with reduced serviceability. The wall thickness of the whole fitting body and the pipe connection must be at least -12.5% of the normal wall thickness.

Type B pipe bend:

The fittings have an increased wall thickness on the inside of the bend body. The internal compressive strength is equivalent to that of a pipe of the same outside diameter, wall thickness and material. For this reason, it is also referred to as a pipe bend with full utilisation. The wall thickness on the inside of the bend must be increased compared to the wall thickness of the joint. The required wall thickness is calculated using a complex formula that takes into account the outside diameter, the wall thickness and, in particular, the bend diameter. As a result, pipe bends with particularly narrow bend diameters require significantly increased wall thicknesses on the inside.

Difference between EN10253-2 and EN10253-4

The EN10253-2 and EN10253-4 standards classify pipe bends into two different types, whereby they are given different designations in the current standards. In EN10253-2, they are designated as type A and type B, while EN10253-4 designates them as type A and type B.

Seamless elbow 76.1 x 12.5 – 2D Bending diameter 126

Type A Wall thickness inside: 11.0 mm

Type B Wall thickness inside: 16.8 mm

Part 1 or Part 2

DIN 2605 refers to a reduced or full utilisation ratio. In the case of full utilisation, i.e. a Part 2 bend, the wall thickness is also significantly thicker in the inner bend. Unlike 10253, the standard does not give a formula for calculation, but lists the corresponding wall thicknesses in tables.

The part 1 elbow has no reinforcement in the inner radius. The same wall thickness tolerances apply over the entire pipe bend.

Differences between the types of elbows

Pipe elbows can vary in outer diameter, wall thickness and bending diameter. The different standards specify so-called standard construction types for the bending diameters. This is intended to help designers with planning by standardising them. In EN and DIN there are the standard types 2D, 3D, 5D and 10D. The American standard ASME B16.9 uses the terms long radius and short radius. These are similar to the bending diameters of the EN and DIN standards. Long Radius is similar to construction type 3D and Short Radius is similar to 2D.

Nevertheless, the standards differ in some places. For example, a pipe elbow with an outer diameter of 101.6 mm as type 2 EN10253-2:2008 has a bending diameter of 190.0 mm. However, the elbow with the same dimensions as a short radius according to ASME B16.9 only has a bending diameter of 177.8 mm. This pipe elbow as type 5D has a bending diameter of 415.0 mm according to EN10253-2 :2008, whereas this is 410 mm according to EN10253-4 (for austenitic steels). One should therefore pay close attention to avoid confusion.

Pipe elbows with tighter tolerances on the bending diameter are often required. This is where SIEKMANN comes into play. Our manufacturing processes enable tolerances that are significantly more precise than the standards. For example, the tolerance on the bending diameter according to EN10253-2 is +/-7mm. We can supply elbows with a tolerance of +/- 1mm on the bending radius.

Table Differences between types 2D, 3D and 5D

The following table shows a comparison of the construction types (center to end) for the different standards. The information is without guarantee.

Attention: Since 2021 there is a new edition of the standard for ferritic steels. EN10253-2:2021, which again partly contains other bending diameters. The table below currently only shows the differences between DIN2605, EN10253:2008 and ASME. For EN10253-4, the 2008 edition is currently still valid.

| Außen- ø | EN10253-2 2021:11 BA 2D | EN10253-2 2008:09 BA 2D | EN10253-4 2008:06 BA 2D | EN10253-2 2021:11 BA 3D | EN10253-2 2008:09 BA 3D | EN10253-4 2008:06 BA 3D | EN10253-2 2021:11 BA 5D | EN10253-2 2008:09 BA 5D | EN10253-4 2008:06 BA 5D |

|---|---|---|---|---|---|---|---|---|---|

| 17,2 | |||||||||

| 20,0 | |||||||||

| 21,3 | 17,5 | 25,0 | 25,0 | 28,0 | 38,0 | 28,0 | 42,5 | 42,5 | 45,0 |

| 25,0 | 27,5 | ||||||||

| 26,9 | 25,0 | 25,0 | 25,0 | 29,0 | 38,0 | 29,0 | 57,5 | 57,5 | 57,0 |

| 30,0 | |||||||||

| 31,8 | 35,0 | ||||||||

| 33,7 | 25,0 | 25,0 | 28,0 | 38,0 | 38,0 | 38,0 | 72,5 | 72,5 | 72,0 |

| 35,0 | |||||||||

| 38,0 | 32,5 | 45,0 | 45,0 | 82,5 | 82,5 | ||||

| 42,4 | 32,0 | 32,0 | 32,0 | 48,0 | 48,0 | 48,0 | 92,5 | 92,5 | 93,0 |

| 44,5 | |||||||||

| 48,3 | 38,0 | 38,0 | 38,0 | 57,0 | 57,0 | 57,0 | 107,5 | 109,5 | 108,0 |

| 51,0 | 45,0 | 63,0 | 63,0 | 115,0 | 122,5 | ||||

| 54,0 | |||||||||

| 57,0 | 52,5 | 72,0 | 72,0 | 127,5 | 130,0 | ||||

| 60,3 | 51,0 | 51,0 | 51,0 | 76,0 | 76,0 | 76,0 | 135,0 | 137,5 | 135,0 |

| 63,5 | 57,5 | 82,5 | 142,5 | ||||||

| 70,0 | 65,0 | 92,0 | 92,0 | 160,0 | 160,0 | ||||

| 76,1 | 63,0 | 63,0 | 63,0 | 95,0 | 95,0 | 95,0 | 175,0 | 175,0 | 175,0 |

| 82,5 | 77,5 | 107,5 | 190,0 | ||||||

| 88,9 | 76,0 | 76,0 | 76,0 | 114,0 | 114,0 | 114,0 | 205,0 | 207,5 | 205,0 |

| 95,0 | |||||||||

| 101,6 | 95,0 | 133,0 | 133,0 | 237,5 | 235,0 | ||||

| 108,0 | 100,0 | 142,5 | 142,5 | 253,0 | 253,0 | ||||

| 114,3 | 102,0 | 102,0 | 102,0 | 152,0 | 152,0 | 152,0 | 270,0 | 270,0 | 270,0 |

| 121,0 | |||||||||

| 127,0 | 175,0 | ||||||||

| 133,0 | 125,0 | 181,0 | 181,0 | 312,5 | 311,5 | ||||

| 139,7 | 127,0 | 127,0 | 127,0 | 190,0 | 190,0 | 190,0 | 330,0 | 330,0 | 330,0 |

| 146,0 | - | ||||||||

| 152,4 | 215,0 | ||||||||

| 159,0 | 150,0 | 216,0 | 216,0 | 375,0 | 375,0 | ||||

| 165,1 | |||||||||

| 168,3 | 152,0 | 152,0 | 152,0 | 229,0 | 229,0 | 229,0 | 390,0 | 390,0 | 390,0 |

| 177,8 | 250,0 | ||||||||

| 193,7 | 180,0 | 270,0 | 270,0 | ||||||

| 219,1 | 203,0 | 203,0 | 203,0 | 305,0 | 305,0 | 305,0 | 510,0 | 515,0 | 510,0 |

Bending radius

We also manufacture pipe bend dimensions outside the standard 2D, 3D and 5D radii. Our well-positioned tool portfolio allows us to offer many special dimensions in the range up to 219 mm outside diameter.

The following table lists all bending diameters with which we have already produced elbows.

Please also ask for other bending diameters.

| Outer diameter | Bending radius R= |

| 10 | 20 |

| 14 | 20 |

| 16 | 16 |

| 18 | 21 |

| 20 | 16 – 25 – 26,5 |

| 21,3 | 17,5 – 19,5 – 25 – 27,5 – 28 – 38 – 42,5 – 43,5 – 150 |

| 22 | 38 – 45 – 110 |

| 25 | 21 – 25 – 27,5 – 30 – 34 – 44 – 45 – 53 – 60 – 90 |

| 26,9 | 24 – 25 – 25,5 – 28,75 – 29 – 30 – 32 – 34 – 38 – 39 – 40 – 42,5 – 47,5 – 50 – 52,5 – 57,5 – 58,5 – 67,5 – 70 – 85 – 100 – 190 |

| 28 | 28,5 – 32,5 – 33,5 – 35 – 42 – 48 |

| 30 | 25 – 29 – 33,5 – 34 – 35 – 37,5 – 45 – 50 – 55 – 62,5 – 68 |

| 31,8 | 24 – 25 – 27,5 – 30 – 32,5 – 35 – 35,5 – 36,5 – 38 – 39 – 40 – 45 – 50 – 55 – 60 – 63,5 – 67,5 – 80 – 100 – 105 – 112,5 |

| 32 | 25 -28 – 32,5 |

| 33,7 | 22,5 – 25 – 26,5 – 28 – 30 – 31,5 – 35 – 37,5 – 38 – 39,5 – 40 – 45 – 50 – 60 – 72,5 – 125 – 135 – 240 |

| 35 | 25,5 – 38 – 45 – 45 – 46,5 – 60 – 75 – 100 |

| 38 | 25 – 27 – 27,5 – 29,5 – 30 – 32 – 32,5 – 35 – 37,5 – 37,75 – 38 – 38,5 – 39,5 – 40 – 40,5 – 42,5 – 45 – 45,5 – 46,5 – 47,5 – 48 – 50 – 51,3 – 55 – 57 – 57,5 – 59 – 60 – 65 – 66,5 – 70 – 75 – 80 – 82,5 – 83 – 85 – 93 – 99 – 113 – 145 – 190 |

| 40 | 47,5 – 51,5 – 55 – 185 |

| 42,4 | 30 – 31 – 32 – 37,5 – 38,5 – 42,5 – 45 – 46 – 48 – 49 – 50 – 57 – 63 – 65 – 70 – 72,5 – 75 – 80 – 92,5 – 93,5 – 185 |

| 44,5 | 34 – 35 – 40 – 42,25 – 45 – 50 – 51 – 52,5 – 53,5 – 55 – 55,5 – 57,5 – 70 – 70,5 – 80 – 97,5 – 99,5 – 136 |

| 48,3 | 38 – 39 – 40 – 42,5 – 45,5 – 48 – 50 – 51 – 57 – 60 – 75 – 76,2 – 80 – 85 – 100 – 107,5 – 109,5 – 112,5 – 115 – 135 – 249 |

| 51 | 32,5 – 38 – 45 – 46,5 – 47,5 – 51 – 52,5 – 55 – 57 – 61 – 63,5 – 65 – 67,5 – 69,85 – 76,2 – 80 – 92,5 – 115 – 122,5 |

| 54 | 50 – 54 – 72,5 – 97,5 |

| 57 | 42,5 – 52,5 – 53,5 – 57,5 – 66 – 72 – 75 – 77,5 – 84 – 85 – 90 – 92,5 – 102,5 – 104 – 112,5 – 127,5 |

| 60,3 | 38,1 – 40 – 48,75 – 51 – 55 – 57,15 – 60 – 66 – 75 – 76 – 77,5 – 78,5 – 84 – 90 – 95 – 100 – 101,5 – 107,5 – 109 – 117 – 122 – 135 – 140 – 240 – 250 – 350 – 400 |

| 63,5 | 41,25 – 46,5 – 55 – 57,5 – 59 – 64 – 77,5 – 82,5 – 115 – 142,5 – 210 |

| 70 | 50 – 55 – 62,5 – 65 – 75 – 80,5 – 92 – 94 – 95 – 127,5 – 161,5 – 165 |

| 73 | 63,5 – 77,5 |

| 75 | 95 |

| 76,1 | 63 – 70 – 77 – 87,5 – 88 – 95 – 97 – 95 – 105 – 137 – 140 – 140,5 – 150 – 175 |

| 80 | 78,5 – 109 – 160 |

| 82,5 | 63,5 – 77,5 – 79 – 80 – 107,5 – 114,5 – 175 – 190 |

| 85 | 116,5 |

| 88,9 | 57,5 – 58 – 76 – 78 – 80 – 82,5 – 87,5 – 114 – 162,5 – 165 – 185 – 205 |

| 100 | 133 |

| 101,6 | 76 – 89 – 95 – 97 – 133,5 – 150 – 180 – 190 – 237,5 |

| 102 | 126 – 250 |

| 106 | 144,5 |

| 108 | 100 – 101,5 – 142,5 – 200 – 250 – 252,5 |

| 114,3 | 102 – 105 – 116 – 135 – 152 – 220 – 270 |

| 121 | 112,5 – 120 – 152 – 170 – 175 – 282 |

| 127 | 107,5 – 117,5 – 138,5 – 175 – 235 – 300 |

| 133 | 125 – 181 – 250 – 312,5 |

| 139,7 | 127 – 132,5* – 190 – 250* – 270* – 330* |

| 152 | 142,5* – 215* |

| 159 | 150* – 216* |

| 168,3 | 152* – 229* – 390* |

| 177,8 | 250* |

| 193,7 | 270* |

| 219,1 | 203* – 305* |

* nur in 90° herstellbar

SIEKMANN GMBH & CO. KG

Manufacturer for special pipe bends!

For several decades we have specialised in the production of special pipe bends made of seamless pipe. Newly developed production processes, experienced employees and constant control at all stages of production guarantee the highest quality standard.

- Special dimensions

- Production of thick-walled pipe bends

- Production of small batches too

- Large selection of materials to be processed – carbon steel / stainless steel

- Very fast delivery times

- Production of pipe bends with tight tolerances

- Dimension range also outside the standard dimensions

We have made it our business to supply elbows quickly, reliably and of the highest quality. A large selection of tools allows us to manufacture almost any pipe elbow in the dimension range between 14 mm and 219.1 mm – especially in the thick-walled range.

Get to know us on the following pages and feel free to contact us. We are pleased about your interest

If you have an enquiry or would like to contact us, please use the form below. You can also contact us directly. You will find the relevant contact person under the menu item “Contact”.

History

In 1907, the Siekmann company was founded as a village blacksmith’s shop. In the beginning, forged parts were produced for the local agriculture. From 1928, the first products for the heating sector were manufactured. The first pipe bends were successfully produced in 1940. A new production facility was built in Lohne in 1957. The first tests with thick-walled elbows were carried out in 1970. In 1987, the Siekmann company was re-established at the Bünde site. From 1992, production was switched to special pipe bends with thick walls. For this purpose, new production methods were developed which are decisive for today’s success. In the following years, new land was acquired and a new production hall was built. Translated with www.DeepL.com/Translator (free version)

References

- Total S.A.

- Siemens

- Hitachi Power

- Alstom Power

- Exxon Mobil Production

- Buhlmann Rohr-Fittings- Stahlhandel

- STAROFIT Klose GmbH & Co. KG

- ThyssenKrupp Schulte GmbH

- RFF Rohr Flansch Fittings Handels GmbH

- Oschatz GmbH

- Stahl u. Plastic- Flanschen GmbH

- BHR Engineering & Construction

- Piping- Service Steuer Handelsges. mbH